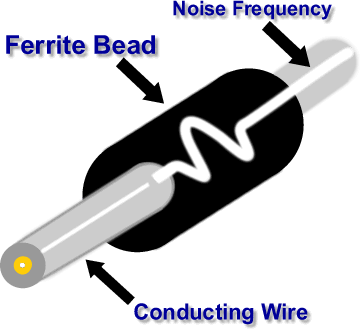

What is a Ferrite Bead?

A ferrite bead, also called cores, chokes or EMI filters, is a passive electrical device that filters high-frequency noise in electrical circuits. It removes the noise in the form of heat (magnetic energy). A ferrite bead consists of a machined piece of ceramic material made of manganese, zinc, nickel and magnesium. When attached to a conducting wire, its electromagnetic properties allow the material to influence the high-frequency current flowing through the wire; reducing the level of RFI (Radio Frequency Interference) and electromagnetic interference (EMI). The interference is prevented from a component and to a component. I recommend filtering wires of the same voltage or type. Do not mix low-voltage, data-wiring and high-voltage wiring through the same filter.

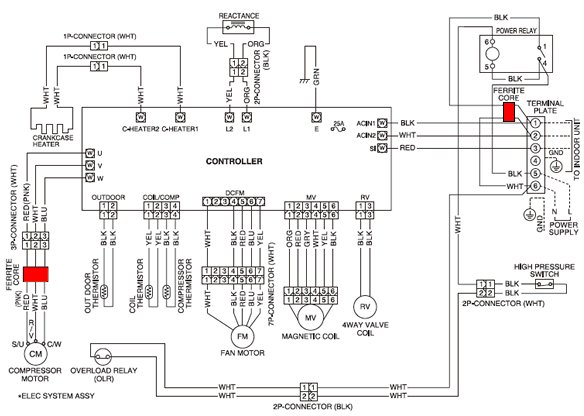

Ferrite Beads installed on an HVAC system.

When an HVAC system is putting out EMI, it may cause an interference in certain devices near the units. Did you ever use an electric drill on the same receptacle as a radio? You get the point. This happens in certain HVAC systems when it affects other devices from operating normally. If you have a customer stating they get an interference on a device when the heat pump kicks on; this is the time to think about using a ferrite choke. Some examples might be televisions, cord-less phones, door bells and radios. I've seen musical equipment, fire and police radios and scanners, and security cameras affected by RFI."An inverter AC operates using pulse signal control (PSC) and high frequencies. Therefore, it is susceptible to the effects of external noise, and is likely to cause electromagnetic interference in nearby wireless devices. A noise filter (ferrite) is installed for ordinary use, preventing these problems. However, depending on the installation conditions, these effects may still occur." -Panasonic Technical Manual for CS-CZ-CU Series

Let's take a look at the wiring diagram of a Panasonic Outdoor Condensing Unit: CU-KE12NK1

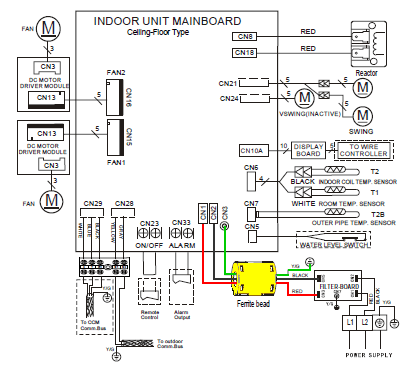

Let's now take a look at the wiring diagram of a Lennox VRF Indoor Unit: MCFA048S4-1P

This ferrite bead is placed over the power supply to and the ground coming from the control board. The wires handle high voltage, so it does not matter if it's supplying a component or coming from a component. Again, this is installed by the manufacturer to assist in any RFI.

When to use Ferrite Beads on an HVAC system.

A ferrite bead has resistive impedance, not reactive impedance. This means it takes energy out of the circuit and removes it as heat (magnetic energy). This does not impede the flow of voltage or amperes flowing through the circuit. If it does, it's minimal. This makes it a near-perfect device for removing high-frequency noise from a circuit. But first, I am going to give you some technical advice to look for before you go putting on beads like it's a Mardi Gras parade. Make sure the system is properly grounded. A system that is not properly grounded can simulate RFI. If you perform an electrical test and find that the system is properly grounded, you can proceed to use a ferrite core.When to use a ferrite filter on an HVAC system? Standard split systems and furnaces will not need a ferrite core installed on the system. Again, I can not stress enough to make sure the system is properly grounded if it is disturbing other devices when it operates. The HVAC systems emitting EMI are high-efficiency units with inverters and those with variable-speed compressors and fan motors.

"Any electronically-driven motor must contend with electromagnetic interference (EMI) primarily caused by the switching of the high currents into the motor. The “noise” created by the switching must be kept out of the wiring of the home where it can and will cause TV and radio interference. The Electronically Commutated Motor (ECM™) has an advantage here, too. It's efficiency is higher than the induction motor so it operates at lower currents to deliver the same power at the shaft. That advantage translates to a cost advantage in the filters needed to keep switching frequencies from the AC power lines. Nevertheless, a blocking filter (ferrite) is always necessary in a variable-speed blower motor. The amount of filtration is critical, however, and all filters are not equally effective." -General Electric

A variable frequency drive (VFD) will generate radio frequency interference (RFI) in the range of 0.5 MHz to 1.7 MHz, and electromagnetic interferencefrequencies (EMI) in the range of 1.7 MHz to 30 MHz.

The performance of ferrite beads to remove RFI and EMI varies according to the ferrite's material and shape. Yes, you can buy cheap ferrite beads. They will lose their magnetic ability in a shorter period of time compared to ones made with higher-quality materials. The magnetic permeability changes according to the ferrite materials, so the impedance (amount it will absorb) will also differ. The material of ferrite beads sold as noise suppressors are manufactured specially for high-frequency noise. You can buy ferrite beads composed of higher-quality materials that are made to absorb magnetic energy without breaking down in a shorter period of time. This is the 'Material' number you look for in a ferrite core. The higher the 'Material' number the higher the permeability of the ferrite core.

For HVAC systems, I suggest a cable clamp-on (snap) ferrite core of Material #31 - #46 with a maximum EMI suppression rate of 300 MHz. Ferrite beads do not have a fixed megahertz rating. I recommend a maximum rating range of 300-500 MHz. The ferrite bead should fit on the wire(s) without slipping or cutting into the wires' insulation. A plastic tie-band can be used to keep the bead from coming apart. Place the filter on the wire(s) as close to the device causing the noise interference. Do not place ferrite filters on control boards or near contactors or capacitors.

When replacing a ferrite core for an HVAC unit that was installed by the manufacturer, use the same MHz rating and type. Filter the same wires as noted on the wiring diagram and wrap the wires around the core as directed. You can use a higher Material number, but never lower than the one being replaced.

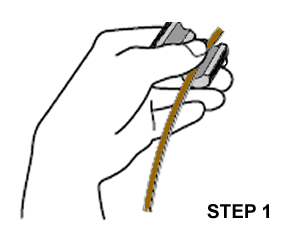

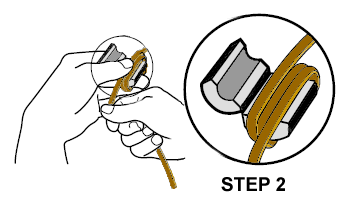

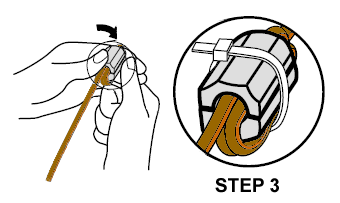

If after installing a ferrite bead, the frequency noise has not diminished; try twisting the wires together before clamping the bead around the wires. If you have enough wiring, wrapping the wire around the bead one or two times will also increase impedance. See Steps 1 - 3.